The oil and gas industry relies heavily on specialized devices to execute exploration, workover, and refinery operations. From boring tools to push control equipment, these necessary devices play a crucial role in removing, handling, and refining oil sources. In this blog post, we will discover some of the essential equipment used in the market and their significance in making sure smooth operations.

Exploration tools are fundamental in the expedition and removal of oil as well as gas books. Drill bits, for circumstances, are responsible for reducing via numerous rock formations throughout the drilling procedure. Advanced designs as well as products, such as polycrystalline ruby compact (PDC) as well as diamond-enhanced inserts, have considerably boosted their sturdiness and efficiency, leading to a lot more reliable exploration operations.

Boring and workover tools incorporate a variety of equipment called for during the boring as well as workover stages. Drilling rigs are huge frameworks that house the exploration devices and give assistance for the drilling procedures. Well control systems, including blowout preventers (BOPs) and also choke manifolds, are critical for keeping safe exploration and manufacturing procedures.

Oil refinery tools is vital in transforming unrefined oil right into functional items, such as gas, diesel, as well as jet fuel. Key equipment includes purification towers, catalytic converters, hydrotreaters, as well as fractionating columns. Annular BOP into different parts based on their boiling factors.

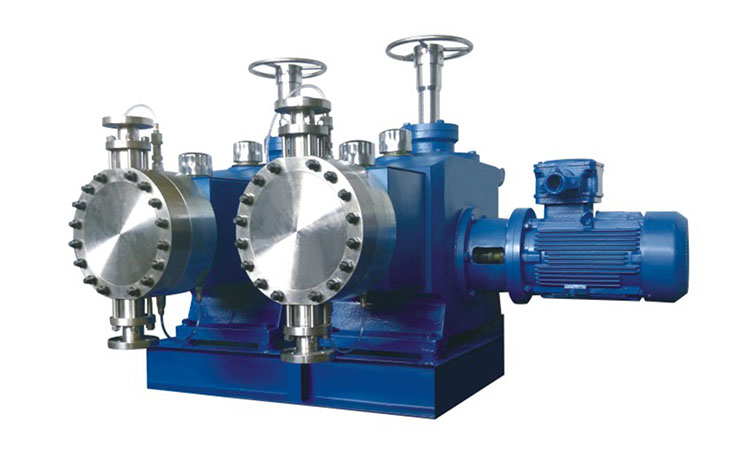

Pressure control tools is essential for maintaining safe drilling and manufacturing operations. In addition to blowout preventers, stress control equipment includes choke valves, eliminate shutoffs, and also stress relief systems. Choke shutoffs control the circulation rate of liquids as well as gases throughout drilling, while kill valves supply a way to stop circulation in instance of emergencies. Pressure alleviation systems, such as relief valves and tear discs, are developed to launch excess pressure and avoid tools damages or failing. These systems work together to maintain risk-free stress levels and guarantee functional stability.

During drilling operations, drilling fluids bring pierced cuttings to the surface area for separation and also disposal. Solids regulate systems play a substantial function in this process. They eliminate unwanted solids from the boring mud, enabling it to be recycled, minimizing ecological impact as well as functional costs. Solids control devices includes shale shakers, centrifuges, desanders, desilters, as well as mud cleaners. Shale shakers utilize shaking displays to divide bigger cuttings, while centrifuges use centrifugal pressure to different finer fragments. Desanders and also desilters better get rid of sand as well as silt-sized particles, specifically. Mud cleansers combine hydrocyclones and screens to accomplish reliable solids elimination.

Centrifugal pumps are extensively made use of in the oil and gas industry for numerous applications, consisting of boring, production, and also refinery procedures. These pumps supply the required stress to distribute drilling mud, transfer liquids between different stages of refining, as well as preserve the circulation of fluids throughout the system.

The oil and also gas sector heavily depends on specialized equipment to carry out drilling, workover, and also refinery procedures successfully. From boring tools as well as workover gears to pressure control devices and warmth exchangers, each component plays an important duty in making certain secure and also effective procedures. By buying innovative devices as well as technologies, the sector continues to improve its capabilities, boost safety criteria, as well as enhance the removal and refining of important oil resources. These important devices allow the sector to satisfy growing power demands while reducing environmental influence and making the most of functional efficiency.